Green Ecological Construction Industry Innovation Magnesium Oxide MGO Sulfate Board

Basic Info.

| Surface Finishing | Slurry |

| Edge | Square |

| Shape | Square |

| Refractory Temperature | 1200degrees Celsius |

| Usage | Building |

| Transport Package | Pallet |

| Specification | 1220*2440 |

| Trademark | WR |

| Origin | Shandong |

| HS Code | 680800 |

| Production Capacity | 2000 |

Product Description

Why is MgO A Better Environmental Product ? MgO - The New Generation Building Material

Magnesium Oxide Board (usually called MGO Board) is the building material widely used in the construction area. The stable magnesium colloid is reinforced by middle alkali glass fiber net and stuffed by light material,then becomes new frameless decorative material. 100% no asbestos contained and no radioactivity.Magnesium oxide more commonly called magnesia is a versatile mineral that when used as part of a cement mixture.And cast into thin cement panels under curing procedures and can be used in residential & commercial building construction.MgO magnesium board are suitable for a wide range of general building uses and for applications that require fire resistance,mold and mildew control, as well as sound control applications and many other benefits.Magnesia boards are used in place of traditional gypsum drywall as wall and ceiling covering material and sheathing,as well as in a number of other construction applications.

SizeWidth 1220 mm;

Length 2440/2700/3050 mm;

Thickness 3-20 mm.

PS: Additional dimensions and thickness options available upon client's request;

What Is MgO Board Made Of?

Magnesium oxide(MGO), perlite, sawdust, fiberglass mesh etc.

Main Performances Of MgO board

-Fire resistant (Class A1) building material;

-Lighter, more flexible and stable than traditional sheeting systems;

-Time and material saving - dramatically reducing construction costs;

-Environmentally friendly, applying a sustainable production process with reduced CO2 footprint;

-Ideal for time, safety and health sensitive construction applications;

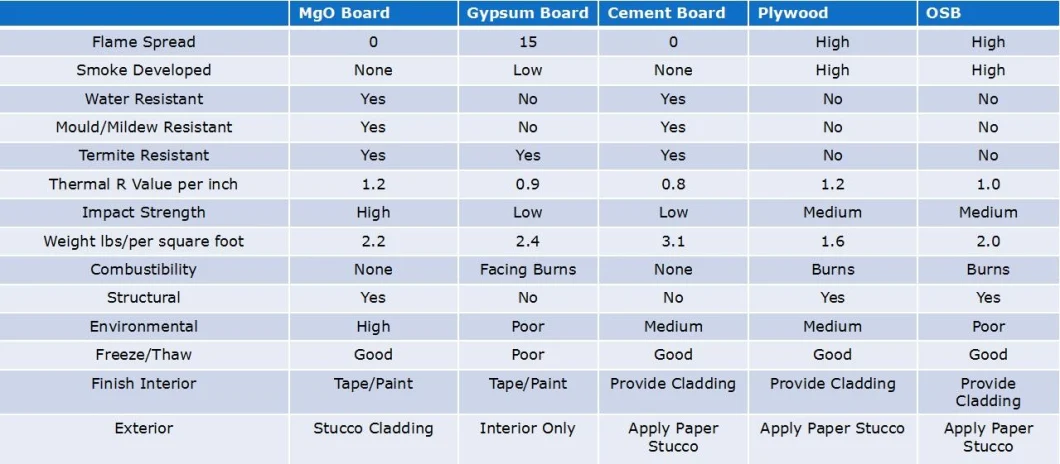

Comparison Sheet

MGO board offers superior performance when compared to wood, gypsum and cement.

Application

Quality Control

1) We are committed to pursuing customer satisfaction by delivering world-class quality products,and services through continuous improvements and innovations.

2) Our quality management system includes Pre-Production Inspection for raw materials, In-Process Quality Control,Container Loading Supervision (Pre-Shipment Inspection).

3) We have a strong system for traceability and immediate status control to make our production efficient, providingfeedback to the product development process.